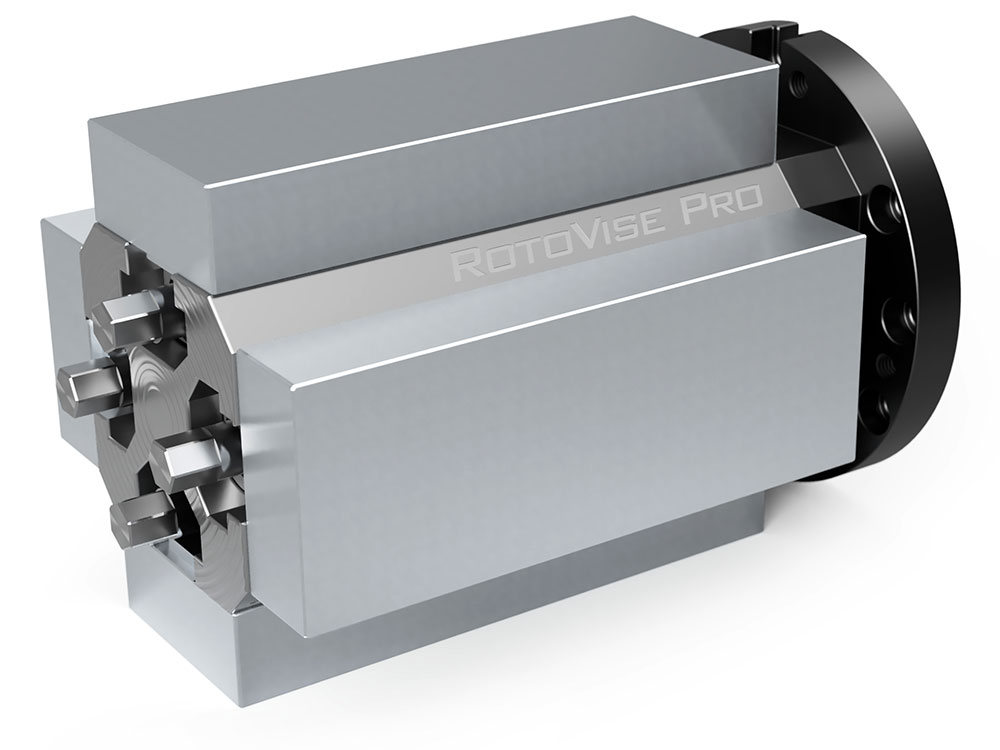

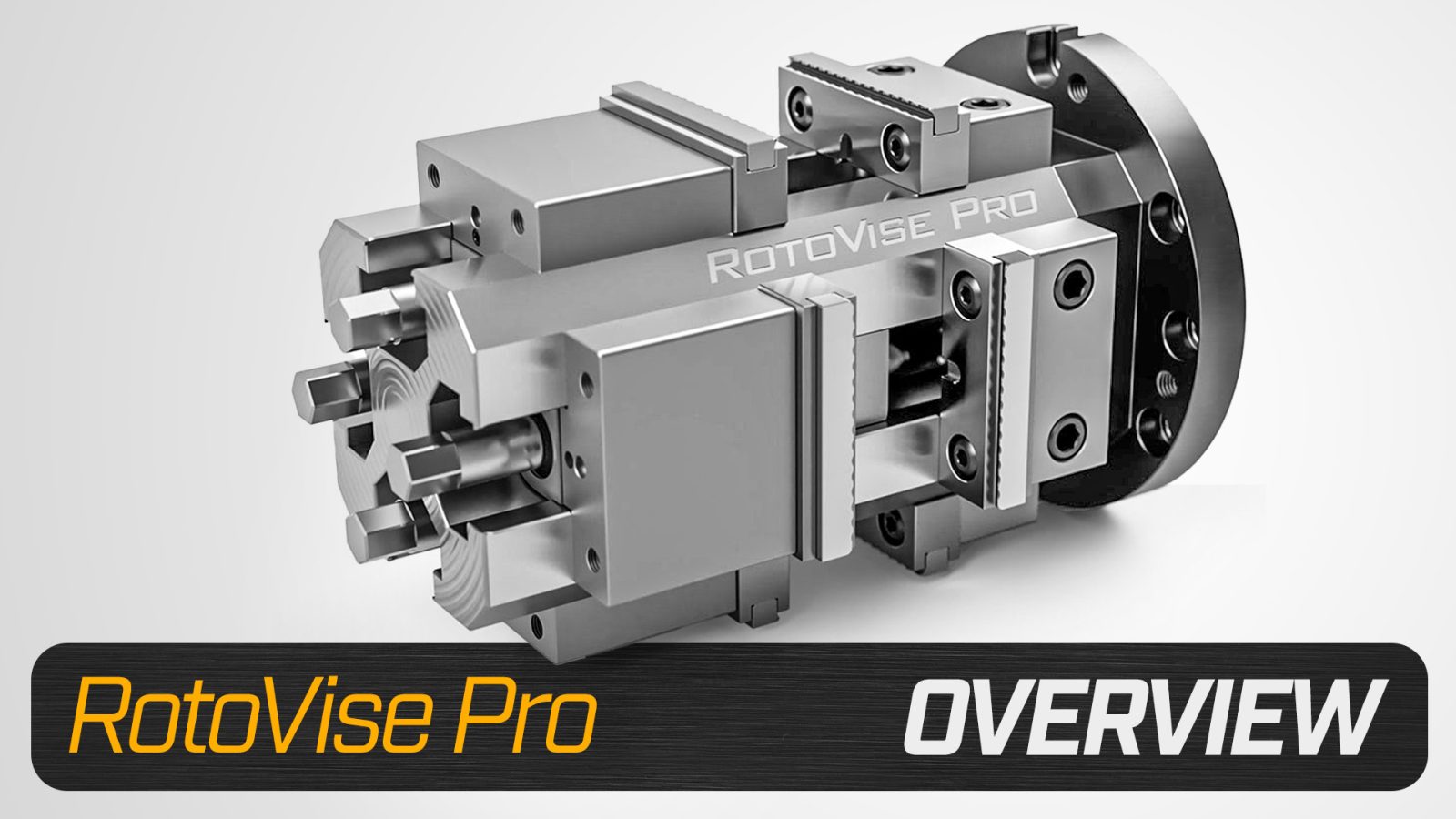

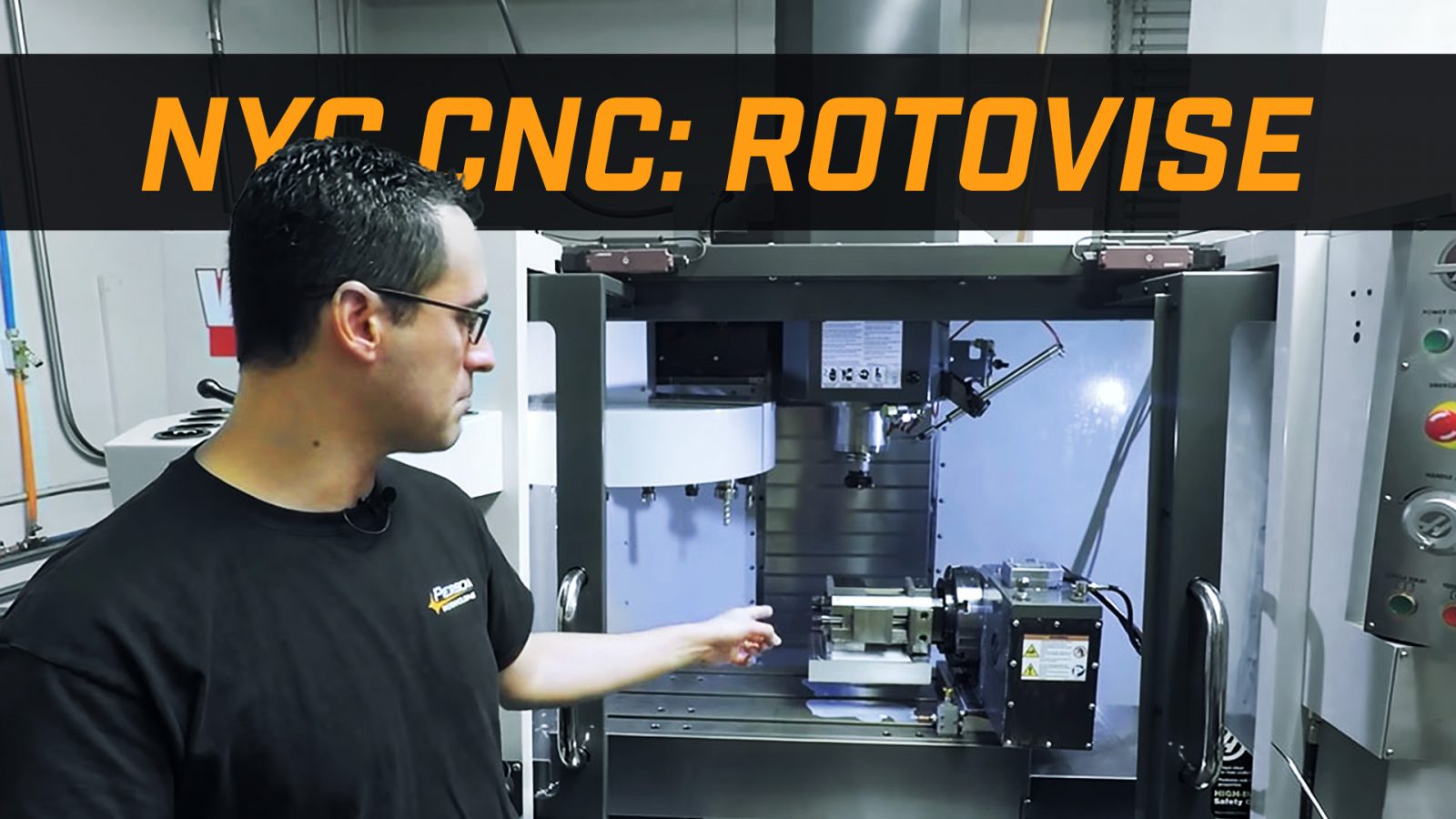

The RotoVise Pro

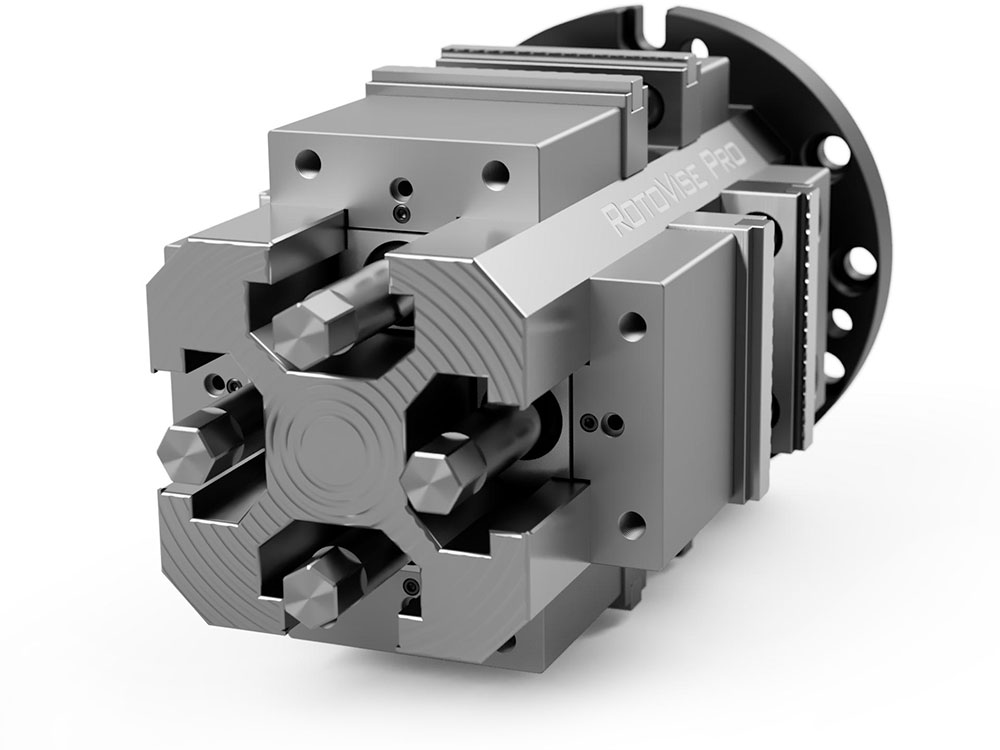

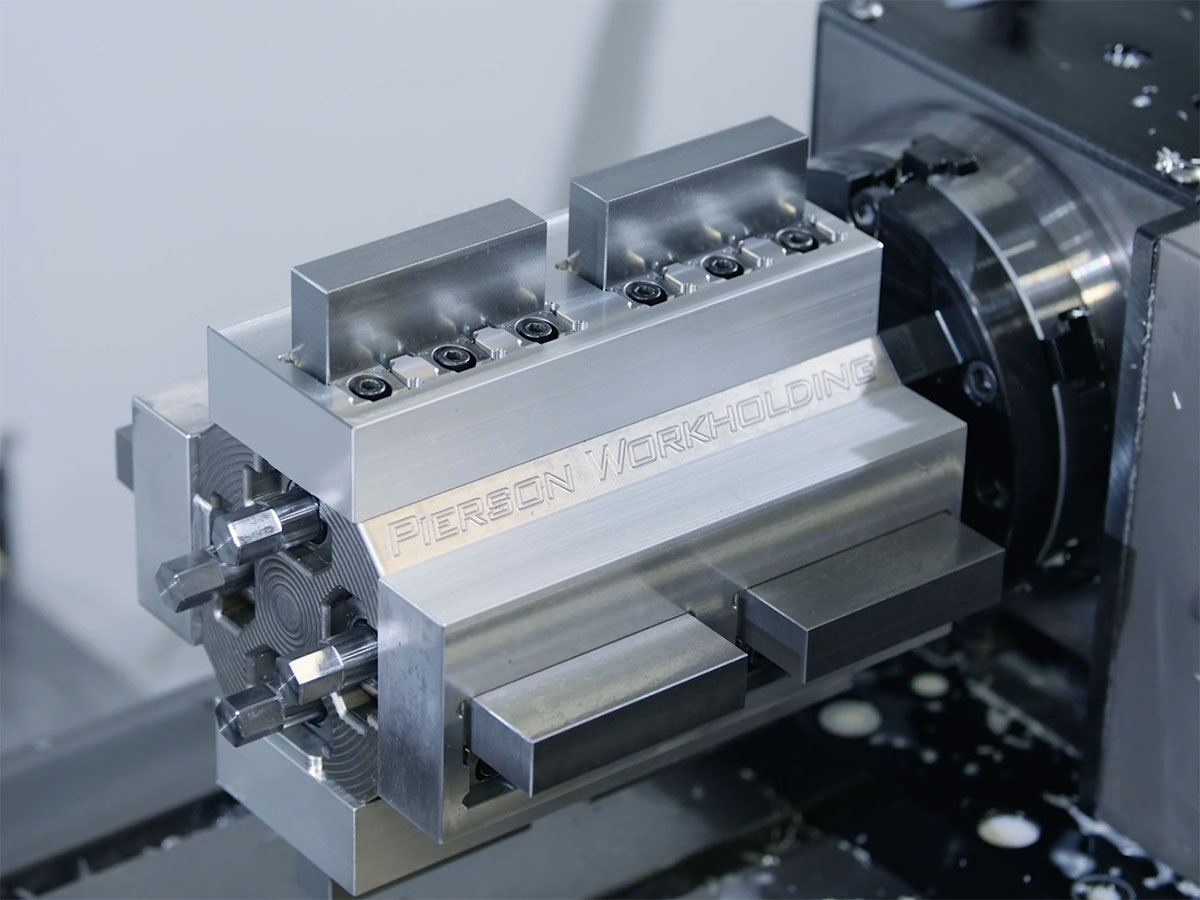

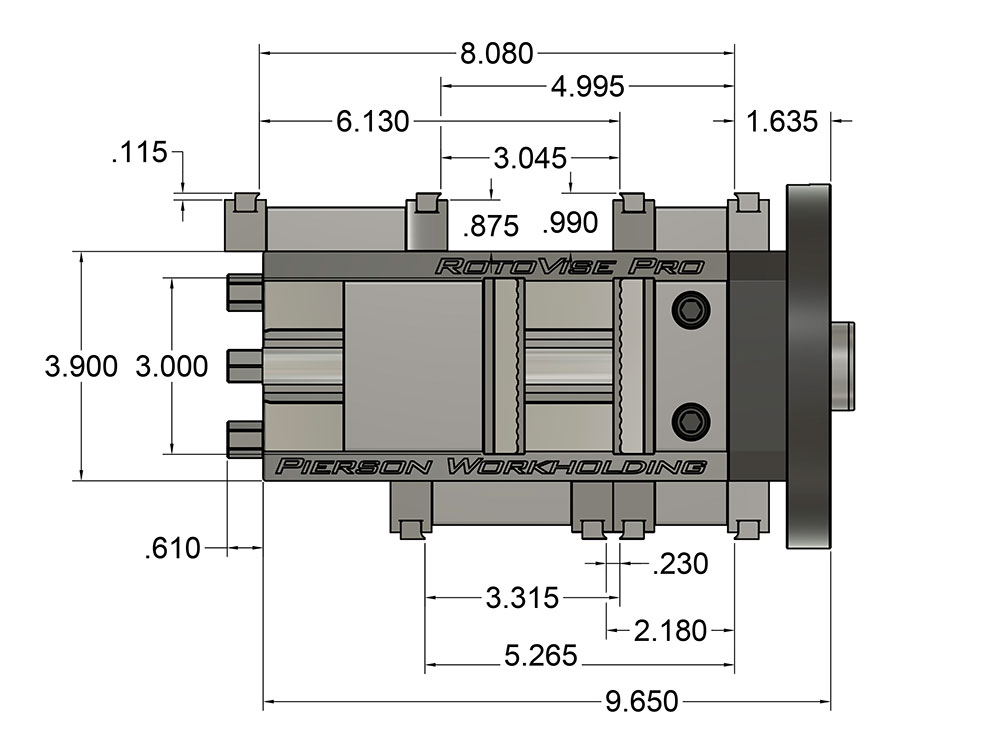

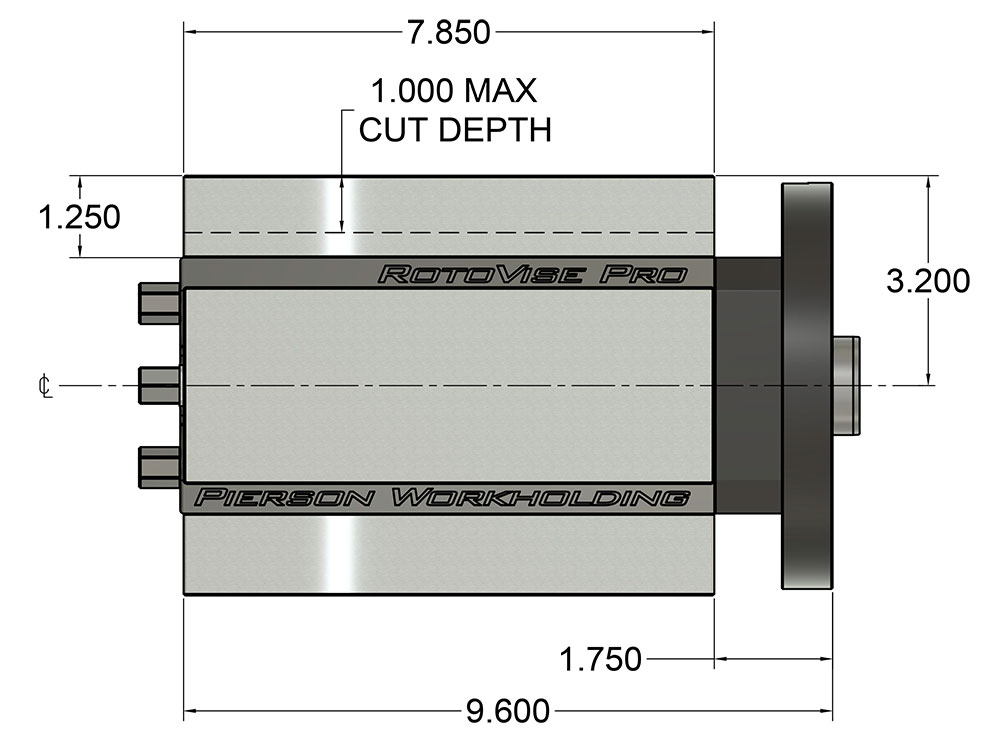

The RotoVise Pro adds an incredible production boost to 4th axis machining. It is a simple and affordable way to get 12x production gains over traditional vise workholding. It bolts to common rotary tables and the compact design does NOT require a cumbersome tailstock due to its rugged construction and parts held close to the face of the rotary unit. Programming is a breeze by patterning toolpaths around the origin at the center of rotation.

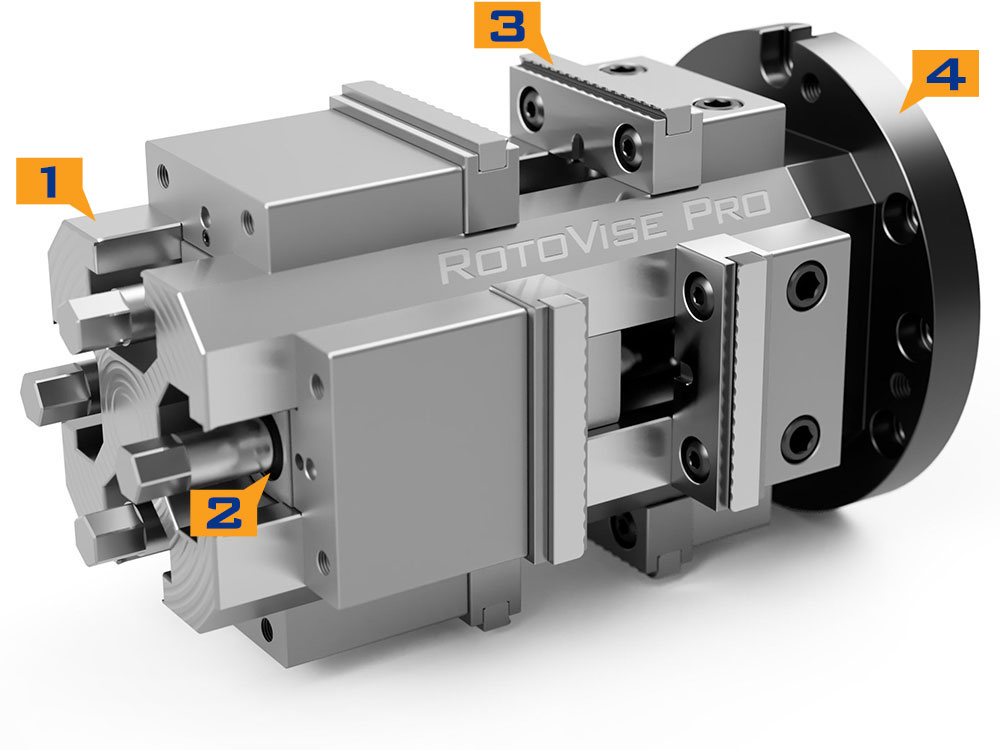

FEATURES

- Ductile cast iron body for maximum dampening, rigidity and long life

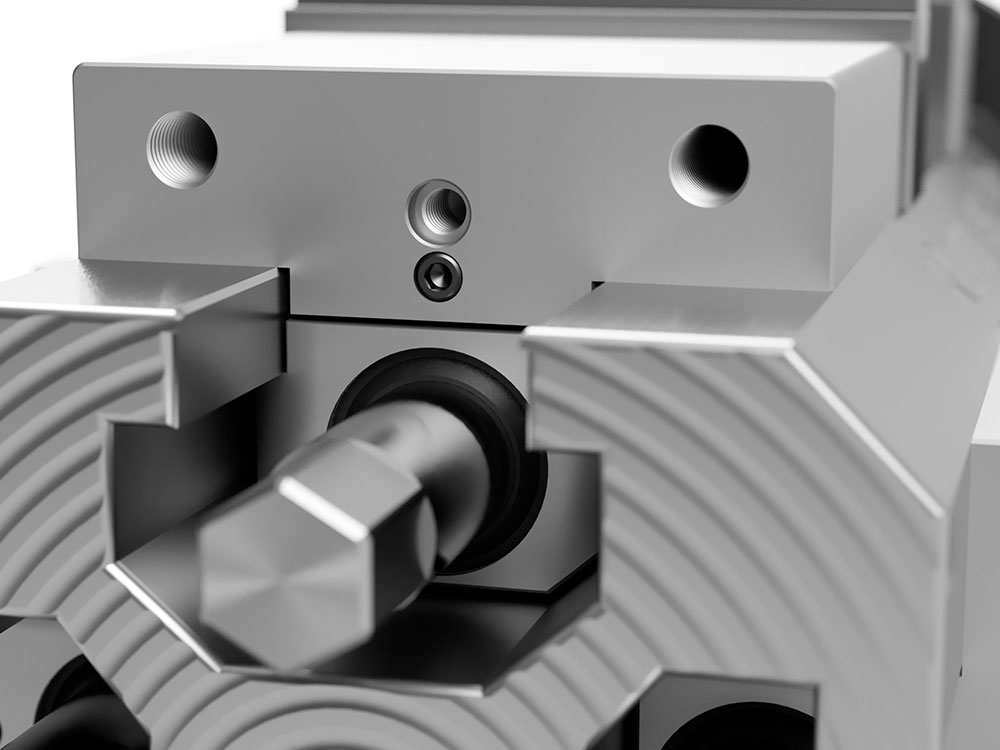

- Sealed lead screws create a smooth action and eliminate chip jamming

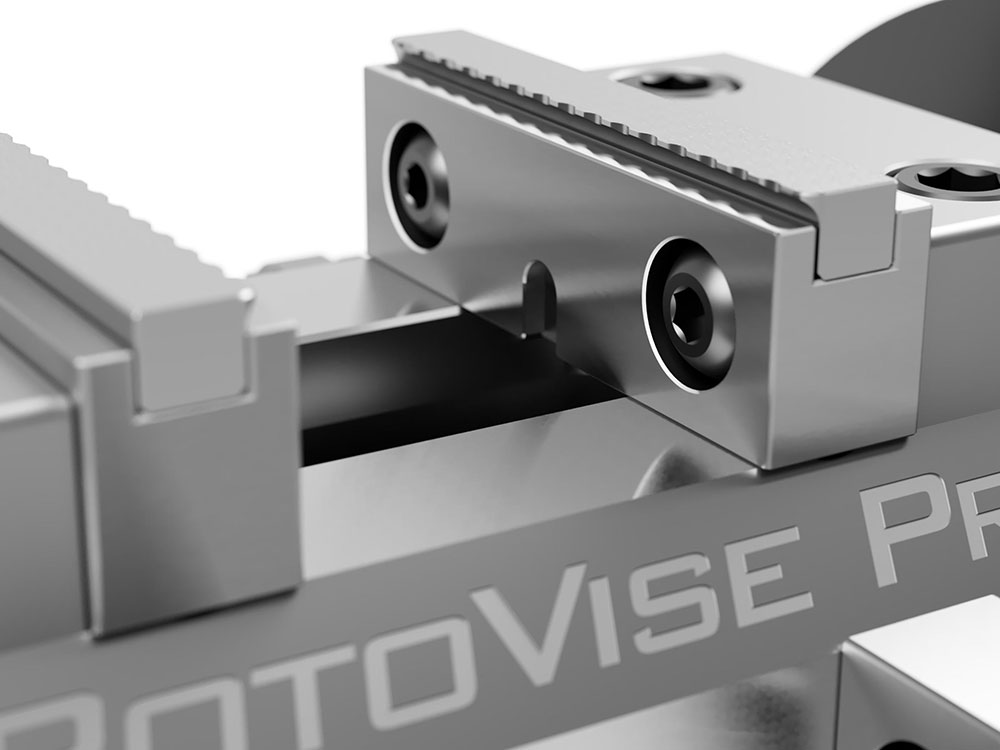

- Hardened steel jaws feature serrated, step and flat sides

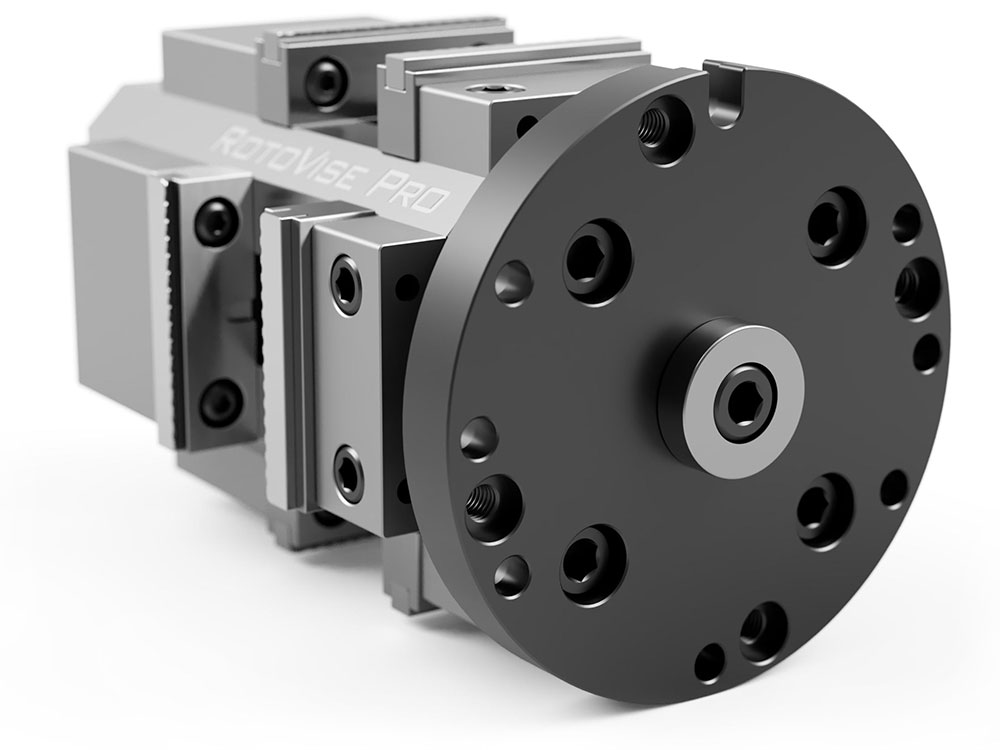

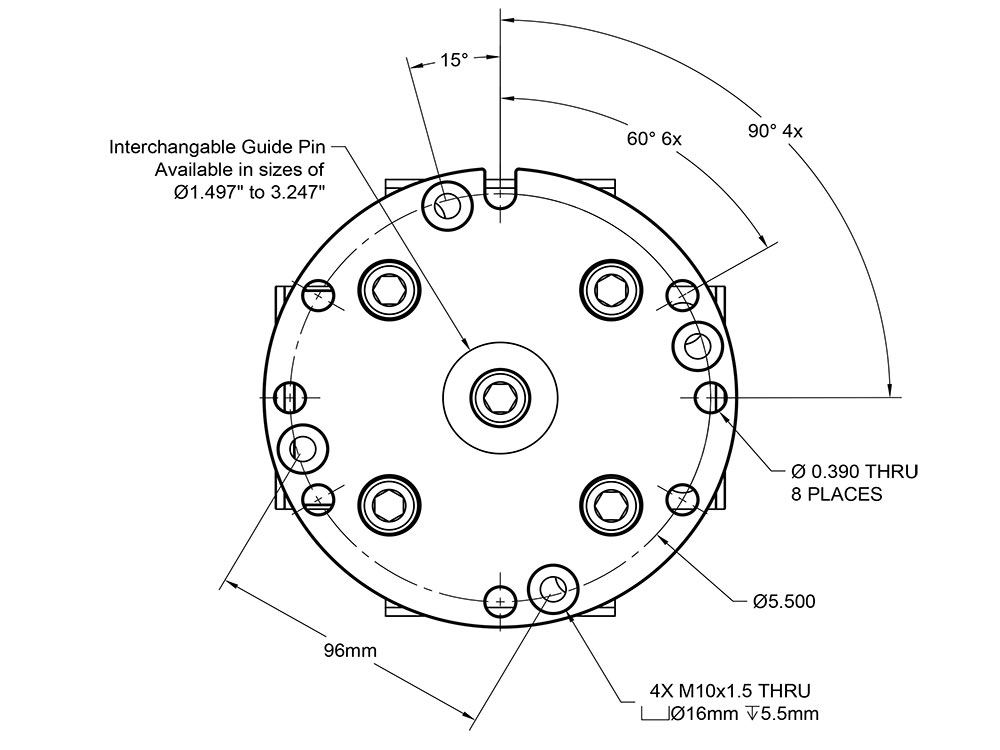

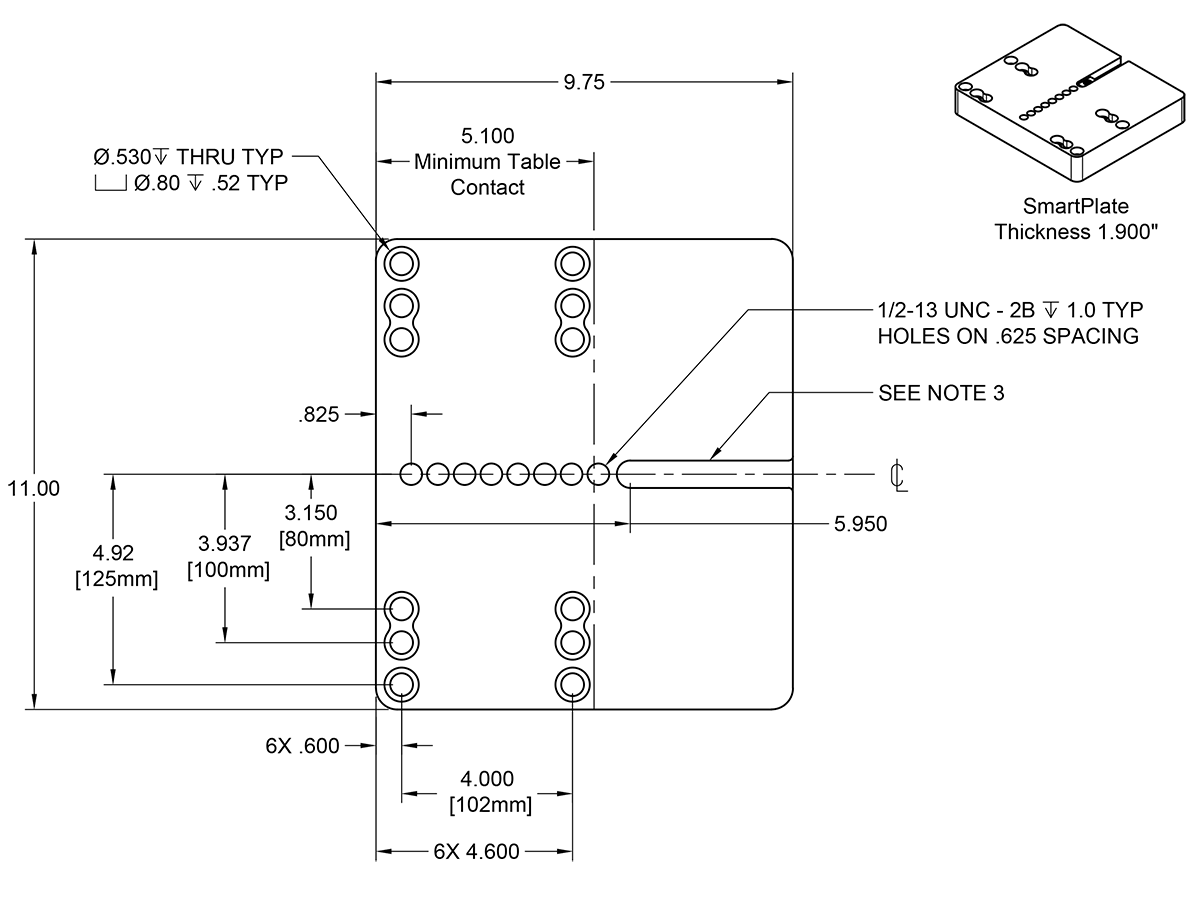

- Adapter plate bolts to 4 and 6 t-slot patterns and 96mm receiver standards

Includes Vise Handle, Serrated Jaws and Guide PinWeight – 45.4 lbs (20.6 Kg)

Includes Vise Handle, Serrated Jaws and Guide PinWeight – 45.4 lbs (20.6 Kg)